25 Best CPQ Software to Close Sales Deals Faster (2024)

- August 12, 2022

Two numbers.

- Gartner Research valued the worldwide CPQ market size at around $570 million in 2015.

- In the same year and by the same research firm, the worldwide CRM market size was valued at around $26.3 Billion.

The CPQ software market was worth a fraction of the CRM market meaning a lot of companies were investing in CRM solutions but very few were purchasing CPQ tools for their sales teams. That, however, was 2015. Now, we’re in 2021. Markets change very quickly.

We don’t know yet if the valuation of the CPQ software market has risen to billions of dollars in 2019. But what we do know, courtesy of Gartner again, is the CPQ solutions market is expanding at the rate of 20% year-over-year. That means it will breach the billion dollar mark pretty fast.

Coming back to the point, you are here to learn about the best Configure-Price-Quote (CPQ) software solutions of 2021. We’ll get to that real fast but not before taking a quick look at what these CPQ tools actually do.

What are the best CPQ software tools for sales teams in 2024?

- DealHub CPQ

- Apttus

- Salesforce CPQ

- IBM CPQ

- Infor CPQ

- Oracle CPQ Cloud

- FPX CPQ

- SAP Configure, Price, Quote

- CallidusCloud CPQ

- PROS Smart CPQ

- Cincom CPQ

- Model N CPQ

- Experlogix CPQ

- CloudSense CPQ

- Accenture bit2win

- Apparound CPQ

- Tacton CPQ

- Axonon Powertrak CPQ

- Autodesk Configure One

- Configit Quote

- EndeavorCPQ

- Sigma CPQ

- Blueprint CPQ

- Verenia Sole CPQ

- ConnectWise CPQ

- QuoteWerks CPQ

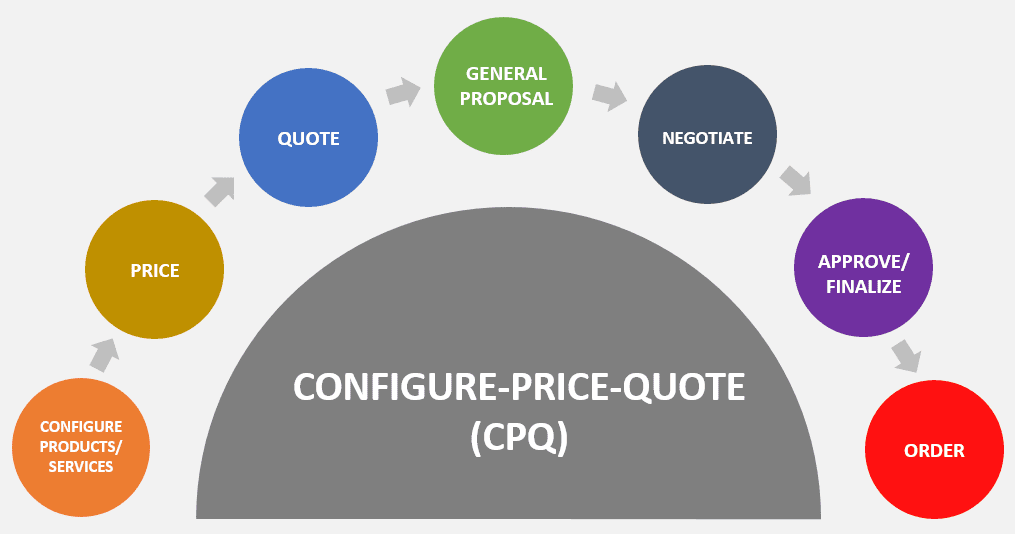

What is CPQ Software?

Configure Price Quote applications help sales reps create high-quality pricing quotes quickly. More often than not, B2B quotes are customized in line with the requirements of the customer and the capabilities of the product. Quotes are nearly always custom-built while discounts come in as well.

Though it might seem like simple mathematics to the layman, building a quote in the B2B sales process is a mind-numbing affair simply because there are many variables and factors which decide the final price. Nobody wants to make a mistake in this area of the sales cycle.

CPQ software relieves sales teams of their pricing migraine helping them build these custom quotes. Of course, that’s not the only advantage – CPQ software tools are quickly turning into must-have applications for enterprises.

It’s important to remember that CPQ tools are different from Quote-to-Cash applications. While CPQ is mostly concerned with generating quotes, the latter ventures further into avenues such as contract lifecycle management making it more of an end-to-end solution.

Benefits of CPQ Software

While this is not an exhaustive list of all CPQ software on the market – it is a list of the 25 best-known and highly-rated CPQ tools available to sales teams in 2024.

1. Reduce repetitive work and help your SDRs and AEs focus on selling

The average sales rep spends 66% of their work week on repetitive, manual tasks such as keying in details into a CRM, creating quotes and invoices manually, etc. That’s 26 hours in a 40-hour workweek spent not selling.

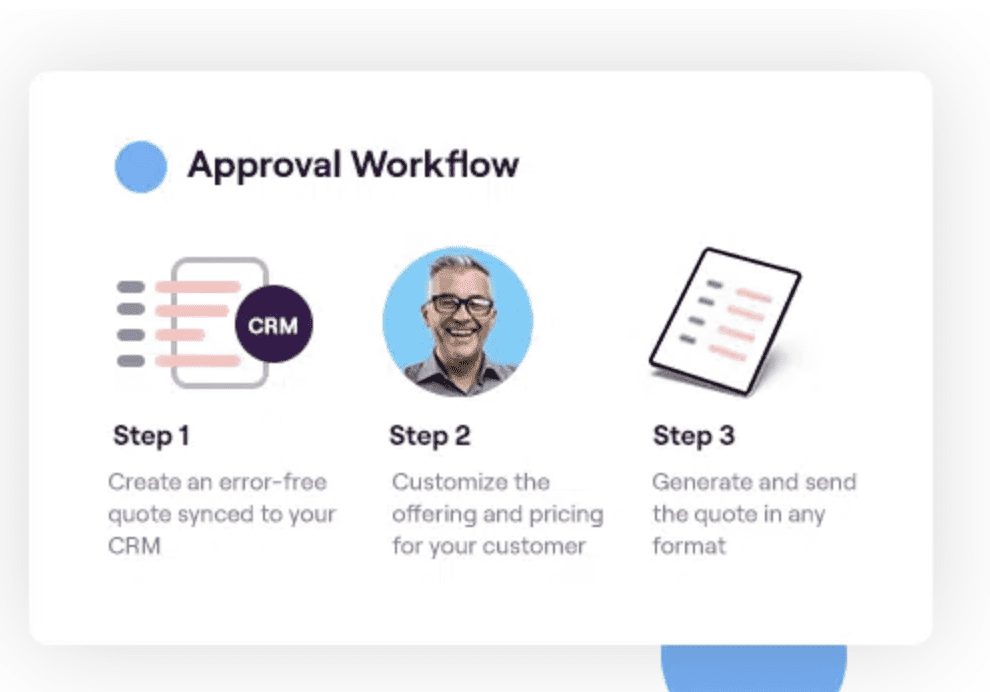

But, according to reports from Salesforce, CPQ software can help sales teams generate quotes 10 times faster, reduce approval times by 95%, and move from quote to cash two times faster. That’s a huge improvement compared to the 4 months it takes 75% of B2B companies to win a customer. This resource goes into depth on those metrics.

2. Speed up the onboarding process for new sales reps

It takes anywhere from 3 – 15 months to fully onboard the average sales representative and training programs can cost anywhere from $500 to $15,000 per day, depending on your company’s size and the expertise of the trainer involved. And you really can’t skimp on either the length of your training programs or the cost, otherwise, you might end up with an ineffective sales organization.

Instead, you can use dynamic quoting and pricing tools to help your sales managers onboard new sales reps 30% faster, since there are fewer manual processes needed to train them to start selling.

3. Generate quotes faster and speed up the sales cycle

According to a study by Accenture, 83% of enterprises use some form of CPQ software, and it’s not unusual for sales teams to witness a 20% — 80% cut in how long it takes them to generate quotes.

26 Best CPQ Software in 2024

While this is not an exhaustive list of all CPQ software on the market – it is a list of the 25 best-known and highly-rated CPQ tools available to sales teams in 2024.

1. DealHub CPQ

DealHub CPQ revolutionizes CPQ solutions with its agile, no-code platform, adeptly managing complex pricing structures without extensive reworking. This approach ensures rapid deployment and cost-effectiveness. Its unified platform streamlines the quote-to-revenue process, including proposal issuance, deal closure facilitation, contract management, and automated subscription and billing. This versatility makes DealHub optimal for businesses seeking streamlined sales operations and effortless scalability in dynamic markets.

DealHubCPQ Overview:

- Bottomline: DealHub CPQ offers an agile, no-code platform for managing complex pricing with rapid deployment and cost-effectiveness.

- Suited CRM: SalesForce, Microsoft Dynamics, HubSpot, FreshWorks, SugerCRM, and API.

- Pricing: Specific pricing details may not be publicly disclosed and can vary based on business requirements.

- Notable Customers: Wix, Gong, Drift, Sisense, SpotOn

2. Apttus

Ironically built on Salesforce’s force.com platform, Apttus is by far the most well-known and widely used CPQ software. Despite being an end-to-end CPQ solution, Apttus still relies on CRM applications for some functions although that’s not a bad thing. Apttus leverages Microsoft Office tools really well with its X Author technology to make the generation of price quotes really simple. Apttus’ SaaS-based CPQ software offering is also said to be utilizing Artificial Intelligence capabilities (from the Microsoft Azure Learning service) for prescriptive data and recommendations.

Apptus Overview:

- Bottomline: Strong core functionalities with a positive vision for the future.

- Suited CRM: Salesforce, Microsoft Dynamics.

- Pricing: Not disclosed publicly.

- Notable Customers: Salesforce, Workday, Adobe, Citrix, Moody’s, ABB.

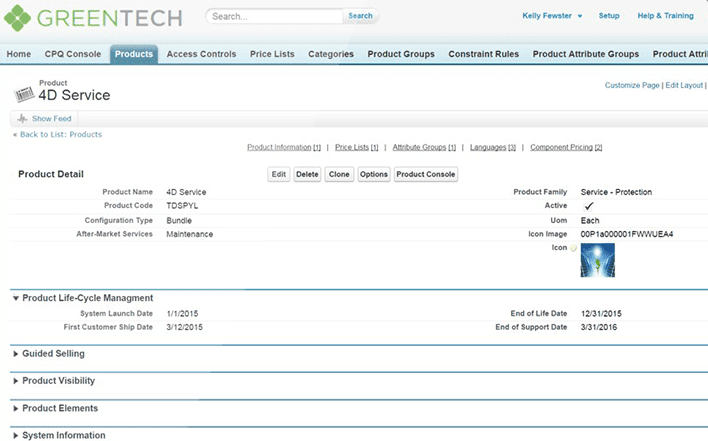

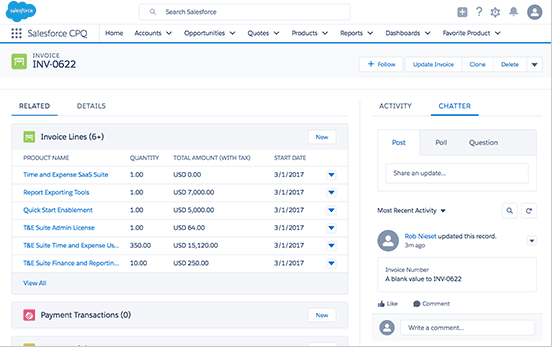

3. Salesforce CPQ

Is it possible that Salesforce has an offering in a niche sector and it doesn’t make the cut? Not really. Originally SteelBrick CPQ, a six years old company led by Godard Abel (now the CEO of G2.com), was acquired by Salesforce in 2015 to fill the CPQ gap on its CRM platform. Piggybacking on the extremely strong CRM presence of Salesforce, its CPQ component has a strong market presence though it is still not the market leader. Salesforce Q2C is a pretty solid piece of CPQ software and if you’re using Salesforce, you should strong reasons not to opt for it.

Salesforce CPQ Overview:

- Bottomline: Runs inside the Salesforce Sales Cloud or Service Cloud. Works pretty well for what is expected from a Salesforce product. CPQ tool benefits from Salesforce’s Einstein AI capabilities.

Suited CRM: Salesforce.

Pricing: Starting – $75 per month/per user (10 users minimum).

Notable Customers: Cloudera, Mitsubishi Electric, Barracuda.

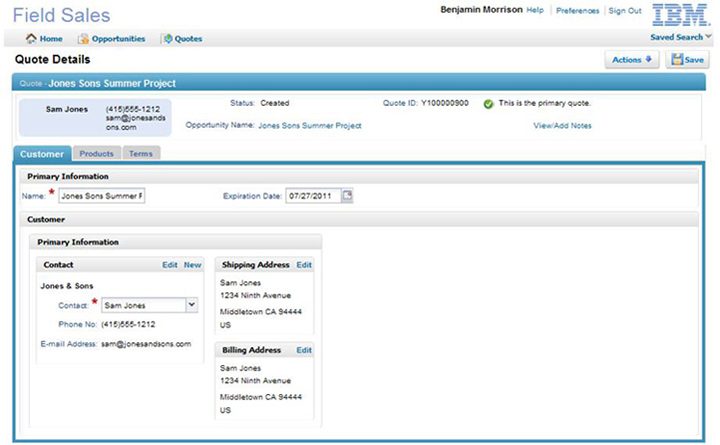

4. IBM CPQ

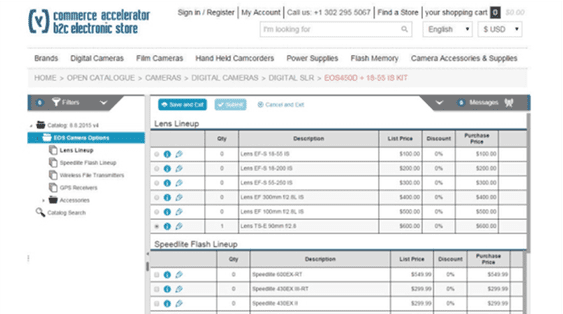

IBM CPQ supports direct sales, customer self-service and partner sales in its multichannel engagements. IBM CPQ provides some very powerful capabilities that suit large enterprises, especially with distributed teams, to get the job done without having to carry out a lot of preliminary activities like duplicating pricing engine rules, inheritances and so on. At the same time, it allows for localization of the pricing engine as well to support distinct geographies. Companies that already have IBM implementations specifically in the e-commerce sphere stand to benefit heavily from IBM’s CPQ software.

IBM CPQ Overview:

- Bottomline: Dynamic pricing engine with multi-level control.

- Suited CRM: Salesforce.

- Pricing: Not disclosed publicly.

- Notable Customers: Not disclosed publicly.

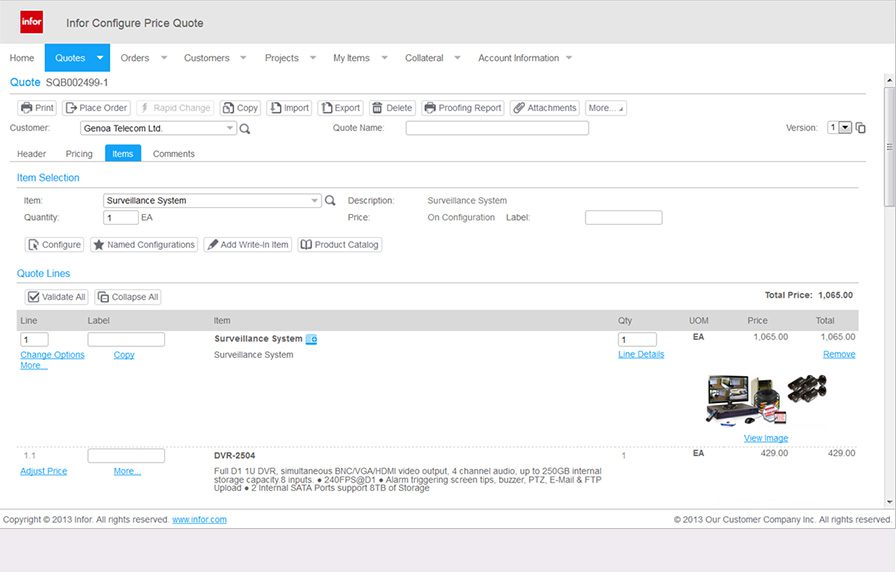

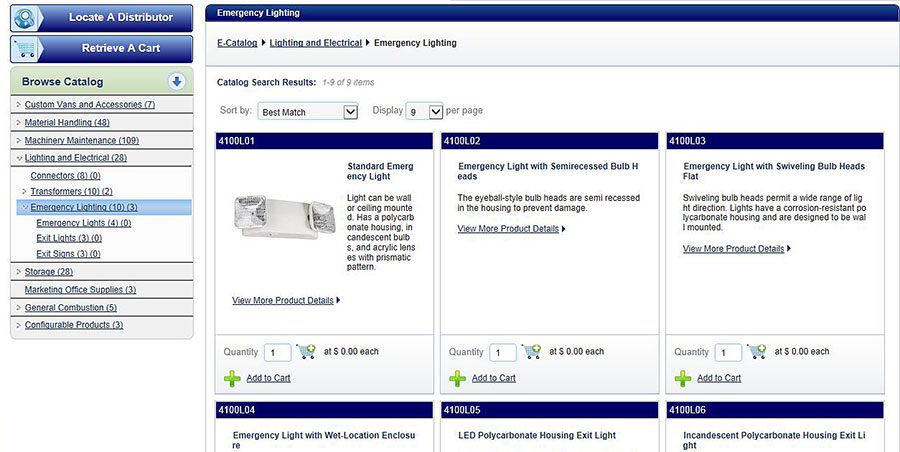

5. Infor CPQ

Infor CPQ solution works well in integrations with ERP solutions with a good set of product features like recommendation engine, custom pricing options and visualizations. Customers, however, complain of shortcomings in ease of use. Infor is also mainly aimed at manufacturing and B2C companies. Infor CPQ also sits well within the universe of enterprise management solutions that Infor provides.

Infor CPQ Overview:

- Bottomline: Robust tool with good core functionalities and support.

- Suited CRM: Infor CRM.

- Pricing: Not disclosed publicly.

- Notable Customers: Huttig Building Products, De Carlo Infissi SPA

6. Oracle CPQ

Known as BigMachines before being acquired by Oracle in 2013, Oracle CPQ Cloud is apt for enterprise-scale implementations with very strong core functionalities. Oracle CPQ Cloud also succeeds in delivering a solid Customer Experience at both ends. Oracle CPQ Cloud can also take advantage of the Oracle Adaptive Intelligence Apps which provide machine learning capabilities. Oracle CPQ Cloud can be used by sales teams as well as a self-service tool for e-commerce sites with integrations available with the Oracle Commerce Cloud.

Oracle CPQ Cloud Overview:

- Bottomline: Strong core functionalities with a brilliant Customer Experience.

- Suited CRM: Oracle Sales Cloud, Salesforce.

- Pricing: Not disclosed publicly.

- Notable Customers: Schneider Electric, Red Hat, PCCW Media.

7. FPX CPQ

FPX is a very old player in the CPQ industry segment and thus is quite mature. FPX’s CPQ software provides a very smooth buying experience irrespective of the channel and is highly customizable and scalable for the specific needs of a company. FPX also integrates with a wide range of CRM and backend technologies. FPX, however, doesn’t seem to have a dedicated mobile presence. Its pricing engine has the capability to keep up with situations that turn complex. Also, it has a very good support team according to reviews.

FPX CPQ Overview:

- Bottomline: Mature product with a well-developed pricing engine and omnichannel suitability.

- Suited CRM: Salesforce, Microsoft Dynamics, SAP

- Pricing: Not disclosed publicly.

- Notable Customers: Honeywell, Airbus, Daimler.

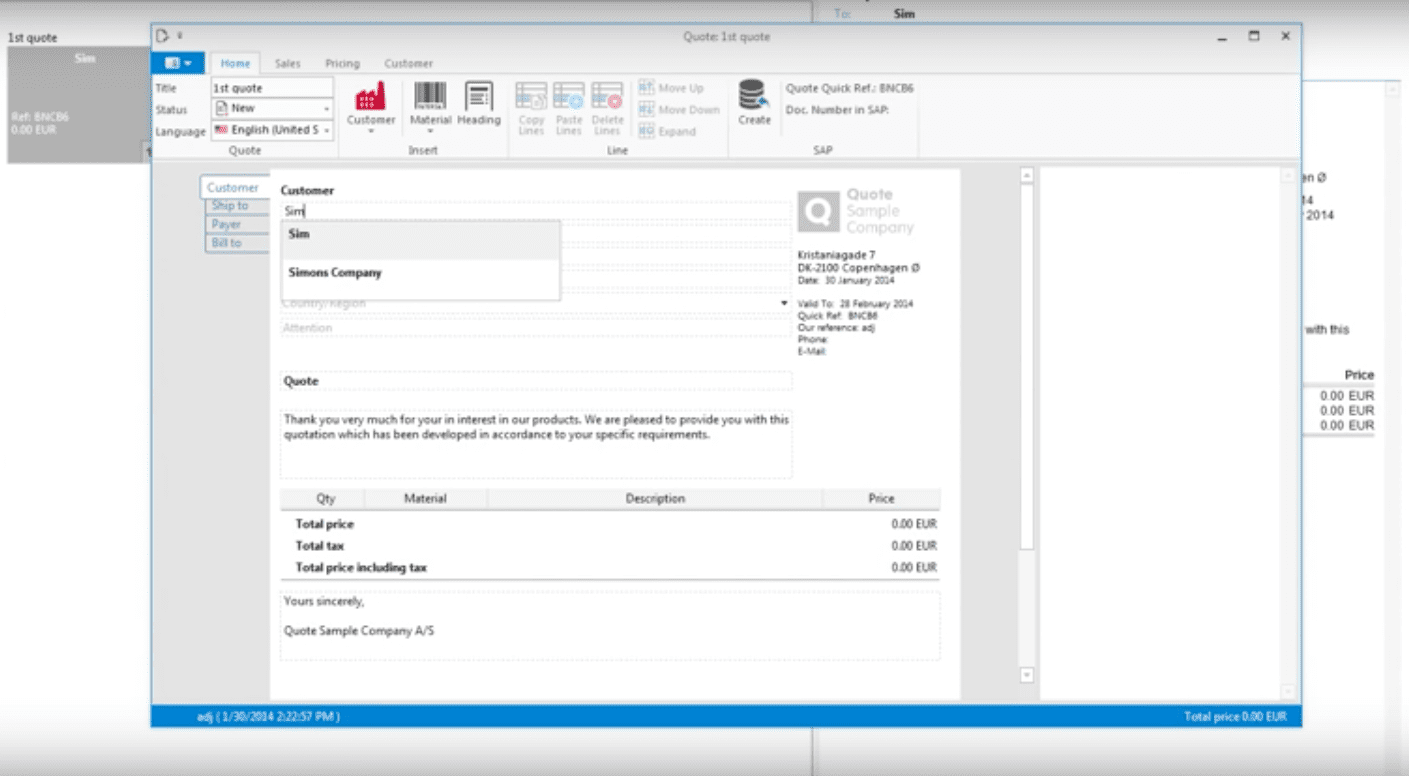

8. SAP CPQ

SAP has somewhat pivoted its Configure, Price, and Quote (CPQ) software solution by adding it to the SAP Hybris platform. SAP CPQ is a worthwhile investment when used in integration with SAP’s products like its ERP and the Hybris e-commerce platform. However, the focus in such cases tends to be more towards the consumer-based e-commerce side while not being helpful to direct sales teams. SAP CPQ provides a scalable configurator engine with a highly intuitive interface that works best when integrated with SAP ERP, as already pointed out, but there is no field mobile presence for sales teams. SAP CPQ also doesn’t have a large market share yet but it is quickly moving towards consolidating parts.

SAP CPQ Overview:

- Bottomline: Best fit for users of SAP ERP and Hybris.

- Suited CRM: SAP.

- Pricing: Not disclosed publicly.

- Notable Customers: EMC

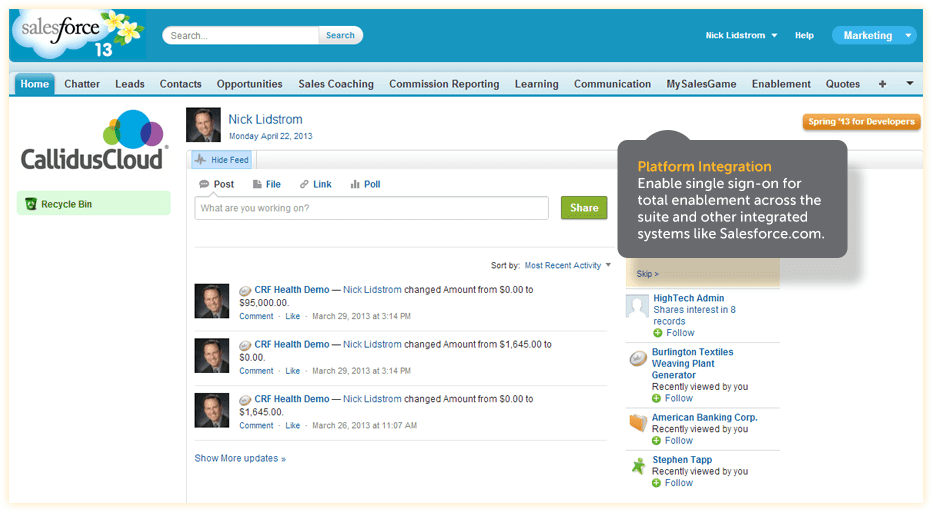

9. CallidusCloud

Callidus Cloud provides a whole range of sales performance management tools of which CPQ is a part. The CallidusCloud CPQ is also a pretty flexible tool which generates quotes fairly quickly. Reviews of this CPQ software have mostly been highly positive considering that it is entirely focused on being as friendly as possible to salesperson. Of course, that should be the case with every CPQ tool in theory, but, in practice, that doesn’t happen all the time. CallidusCloud CPQ provides options for configuration, margin guidance, approval workflows, analytics etc. It is also adding Machine Learning capabilities to its CPQ tool. Support and documentation, however, still has room to improve. All in all, it’s a great CPQ offering with emphasis on data.

CallidusCloud CPQ Overview:

- Bottomline: Highly salesperson-centric with a lot of features.

- Suited CRM: Salesforce, Microsoft Dynamics, Oracle CRM.

- Pricing: Not disclosed publicly.

- Notable Customers: Barclays, Verizon, Palo Alto Networks.

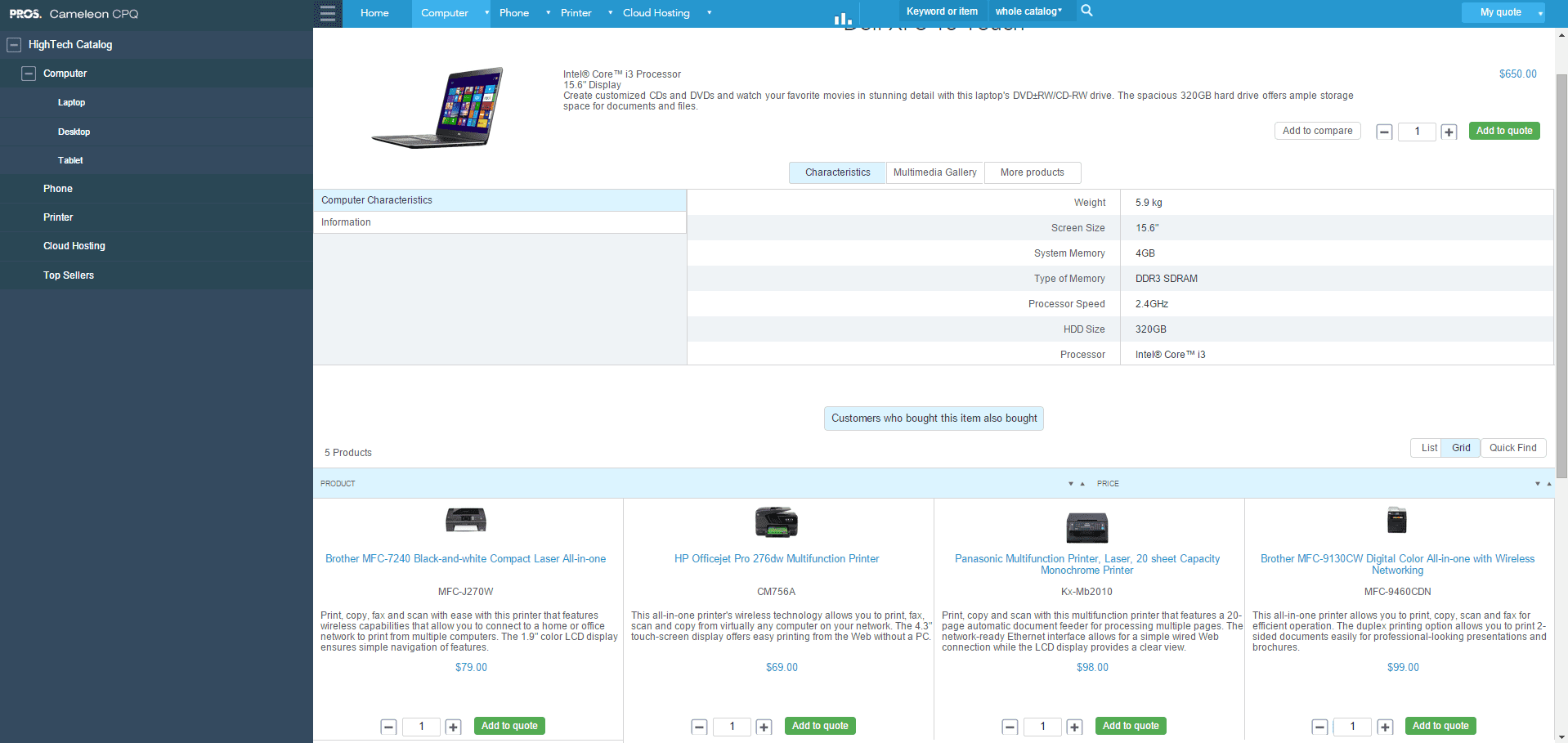

10. PROS

PROS made a dig into the CPQ market with its acquisition of Cameleon CPQ and the results have been good so far. Smart CPQ is a part of the SellingPRO sales solution suite and is more suitable to the manufacturing industries with its capabilities in algorithmic cross-selling and fast pricing configurations. PROS Smart CPQ does well in using data to provide intelligent recommendations leading to direct benefits. Its configurator complexity also helps companies a great deal especially when the market pricing is fidgety. PROS seems like a great fit for the airline industry considering the number of airline customers they have.

PROS Smart CPQ Overview:

- Bottomline: Intelligent recommendations for spot-on pricing.

- Suited CRM: Salesforce, Microsoft Dynamics.

- Pricing: Not disclosed publicly.

- Notable Customers: Siemens, Etihad Airways, Cardinal Health.

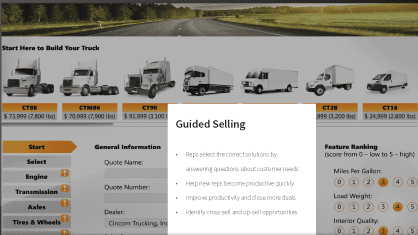

11. Cincom CPQ

Cincom’s CPQ software is highly flexible and agile with a really advanced configurator. Cincom CPQ has been a small team’s dream CPQ tool but that works very well in complex sectors like manufacturing. Plus, it has an efficient sales automation tool that can be used by smaller sales and partnership teams. It is also said to require a fair amount of coding to configure some of the elements but nothing that would require your software developer to spend days on. Users of Cincom also wish for more integrations than it currently provides. Cincom’s CPQ tool provides Business Intelligence capabilities as well and can be deployed in-house or on the cloud.

Cincom CPQ Overview:

- Bottomline: Highly flexible and agile.

- Suited CRM: Microsoft Dynamics, Salesforce.

- Pricing: Not disclosed publicly.

- Notable Customers: Siemens, Carrier, Plantronics.

12. Model N CPQ

Model N is another Salesforce native CPQ solution that is again completely salesperson-centric. Model N also has a bidirectional integration with SAP Variant Configurator. However, it doesn’t really provide e-commerce capabilities while peripheral functionalities like data analytics are also not very strong though it is good fit for certain segments like pharmaceuticals. Model N works best for those who have Salesforce CRM and SAP ERP implementations.

Model N CPQ Overview:

- Bottomline: Beneficial SAP Variant Configurator integrations.

- Suited CRM: Salesforce.

- Pricing: Not disclosed publicly.

- Notable Customers: Merck, Johnson&Johnson, AstraZeneca.

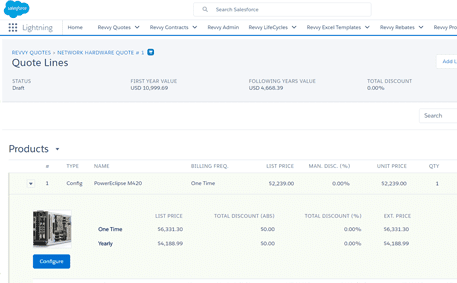

13. Experlogix CPQ

Experlogix CPQ is the Apttus of the Microsoft ecosystem. It was even the ISV of the year for US for Microsoft Dynamics. Experlogix’s CPQ software can be used for multiple sales channels like direct sales teams or resellers or even in both the B2B and B2C environments. Experlogix CPQ provides guided selling, pricing configurator, approvals and automated workflows. It even has a specific CPQ offering for manufacturing companies. Experlogix CPQ is deployed in the Azure cloud and can also be implemented on-premise.

Experlogix CPQ Overview:

- Bottomline: Wide-ranging and well-demonstrated capabilities.

- Suited CRM: Microsoft Dynamics, NetSuite.

- Pricing: Not Disclosed Publicly.

- Notable Customers: Nikon, Kawasaki, Hitachi.

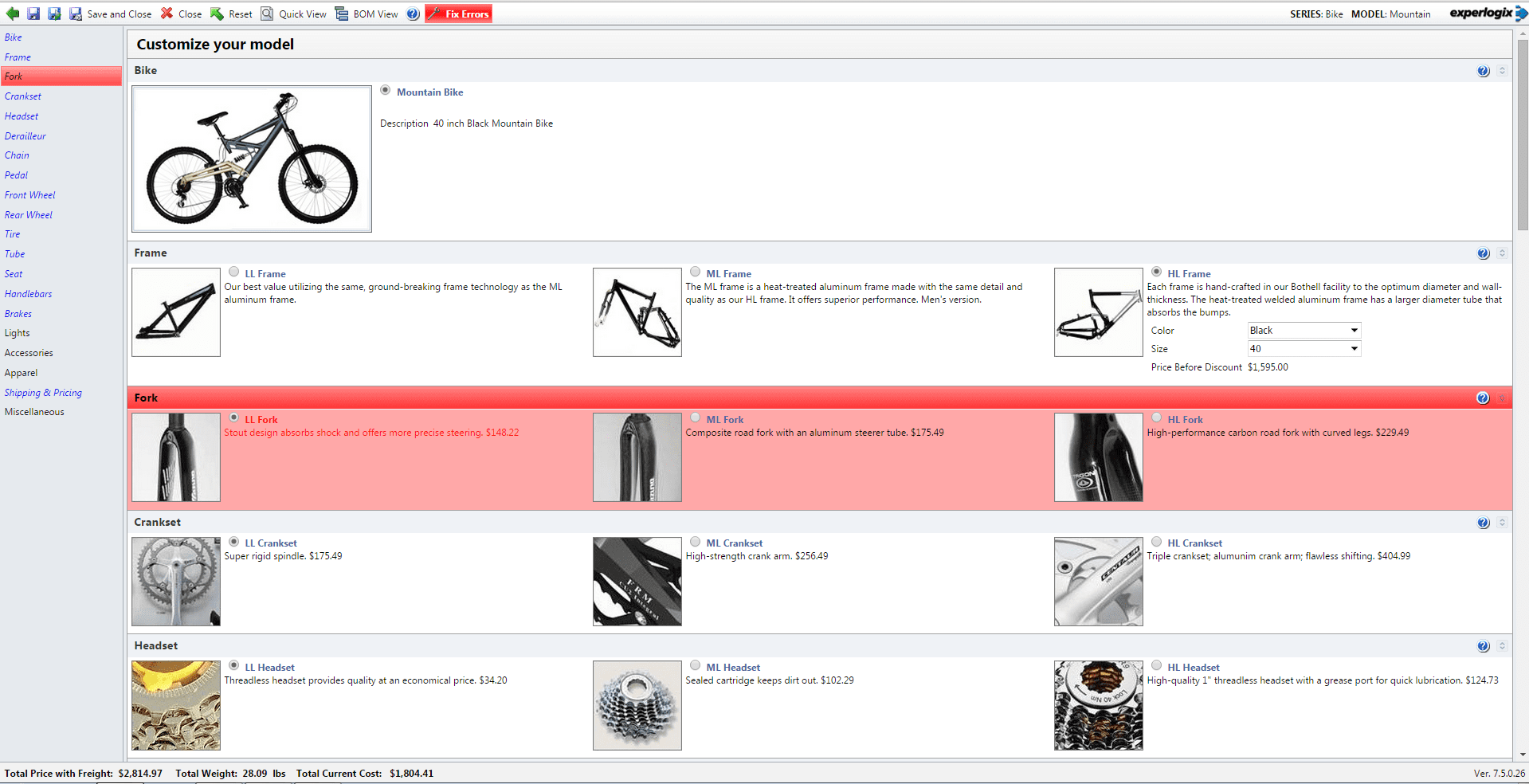

14. Cloudsense CPQ

Native to Salesforce, CloudSense CPQ has specific functionalities for the communications, media, utilities and similar industries. At the same time, it is not just salesperson focussed but is also said to be designed keeping customer service, self-service, field sales and partners in mind. CloudSense provides a lot of out-of-the-box capabilities to model complex situations.

Cloudsense CPQ Overview:

- Bottomline: Salesforce nativity and Lightning ready.

- Suited CRM: Salesforce.

- Pricing: Not disclosed publicly.

- Notable Customers: O2, VodafoneZiggo, Spotify.

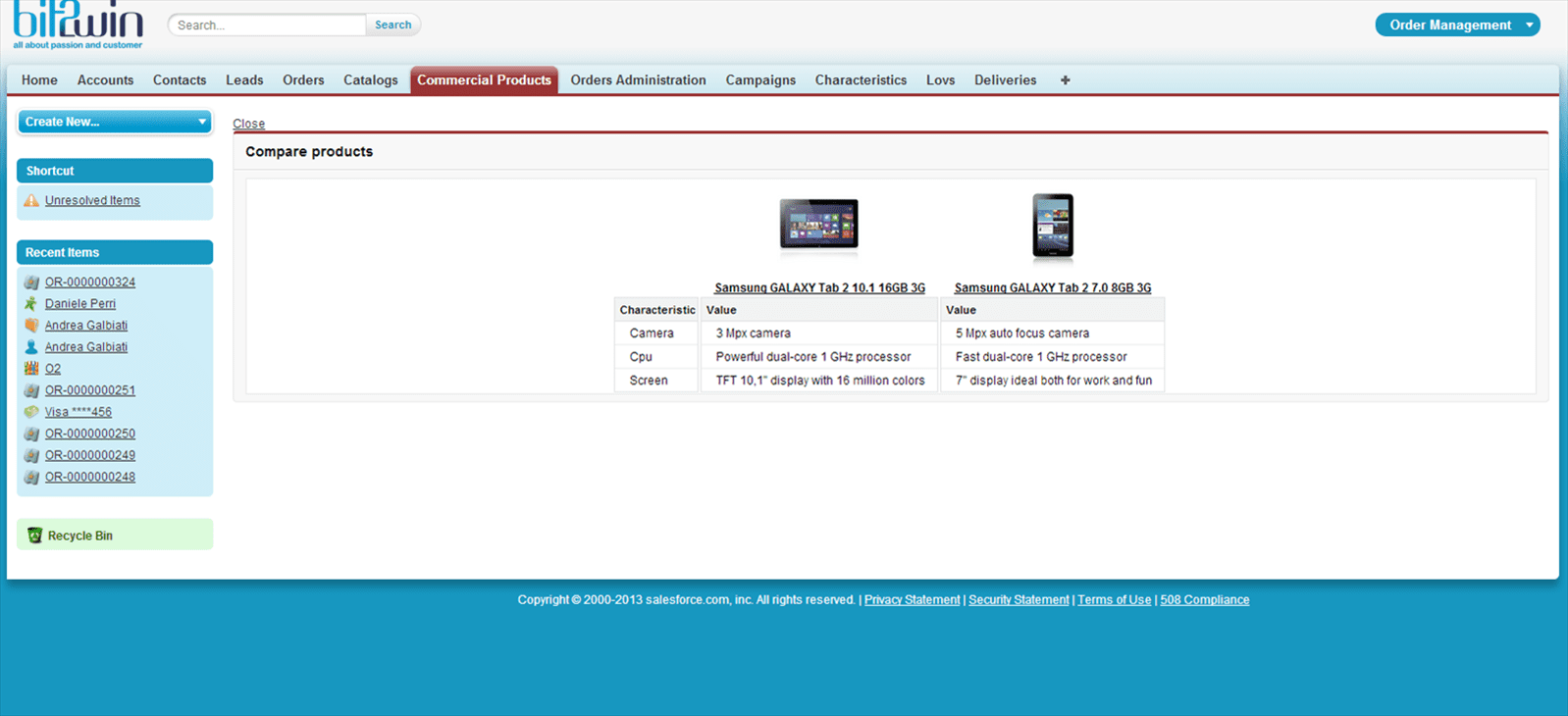

15. Accenture bit2win

Accenture made quite a few acquisitions recently and one of them was the bit2win suite of products. Accenture bit2win Sales is the CPQ software in the suite and is native to the Salesforce1 app. A very light piece of CPQ software, bit2win, however, is not very widely used across industry verticals. bit2win claims that it is aligned very closely with Salesforce’s evolution and product roadmap while also being agile.

Accenture bit2win CPQ Overview:

- Bottomline: Easy to use and omnichannel vision.

- Suited CRM: Salesforce

- Pricing: Not disclosed publicly.

- Notable Customers: Vodafone, Sky Italia, Telefonica.

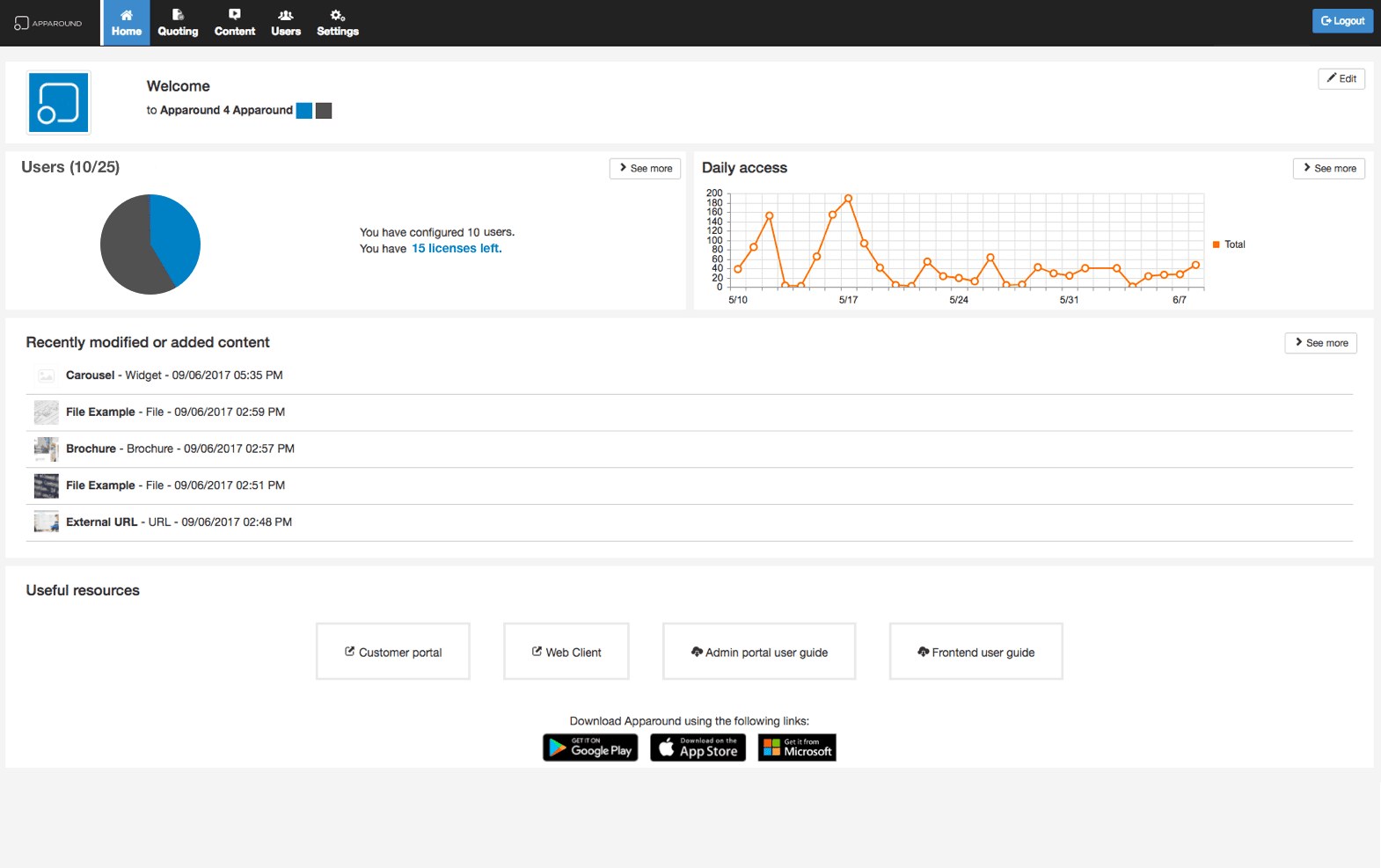

16. Apparound CPQ

Italy-based Apparound’s CPQ software is more focused on the B2C and e-commerce industry segment. That said, it does have a reliable CPQ product offering with the biggest advantage being that it can work offline both on desktop and mobile devices. Offline transactions can be easily synced with any CRM system. Reviews have also suggested that Apparound CPQ is pretty intuitive and easy to use for salespersons.

Apparound CPQ Overview:

- Bottomline: Simple, reliable, intuitive, offline availability.

- Suited CRM: Salesforce, Microsoft Dynamics, Oracle CRM.

- Pricing: € 40.00/user/per month. (10 users minimum; First month free)

- Notable Customers: Pepsi, Vodafone, Allianz.

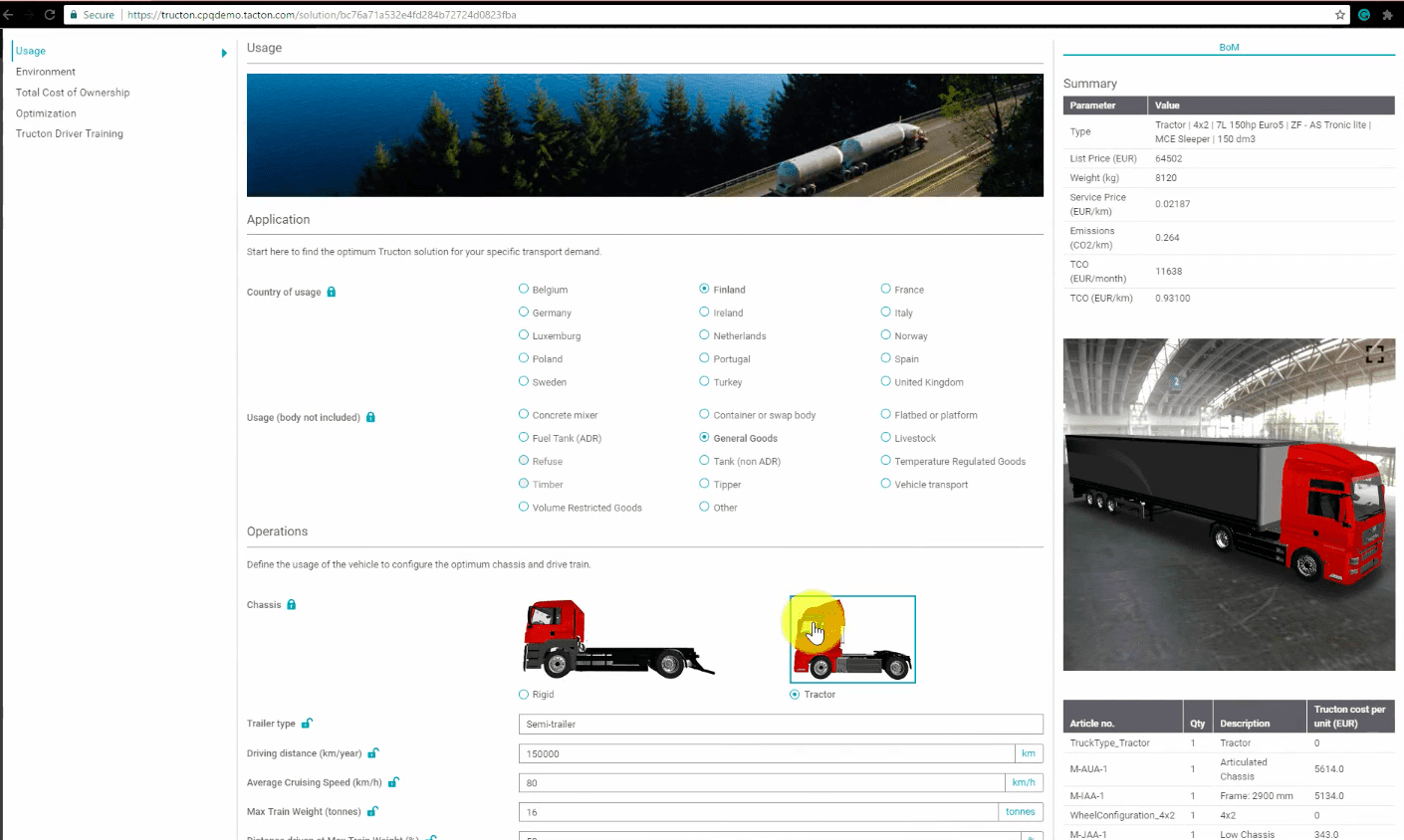

17. Tacton CPQ

Tacton provides another industry specific CPQ software tool. Targeted at the manufacturing industry with 3D visualization capabilities and constraint based configuration. The company says its customer ABB replaced 500,000 configuration rules with just 150 constraints. Tacton CPQ can also be used in a multichannel environment by either direct sales teams or self service customers. Its customers also say that Tacton provides a high level of flexibility with low level of programming expertise.

Tacton CPQ Overview:

- Bottomline: Highly flexible and scalable.

- Suited CRM: Salesforce.

- Pricing: Not disclosed publicly.

- Notable Customers: Caterpillar, Vencomatic, Meyn.

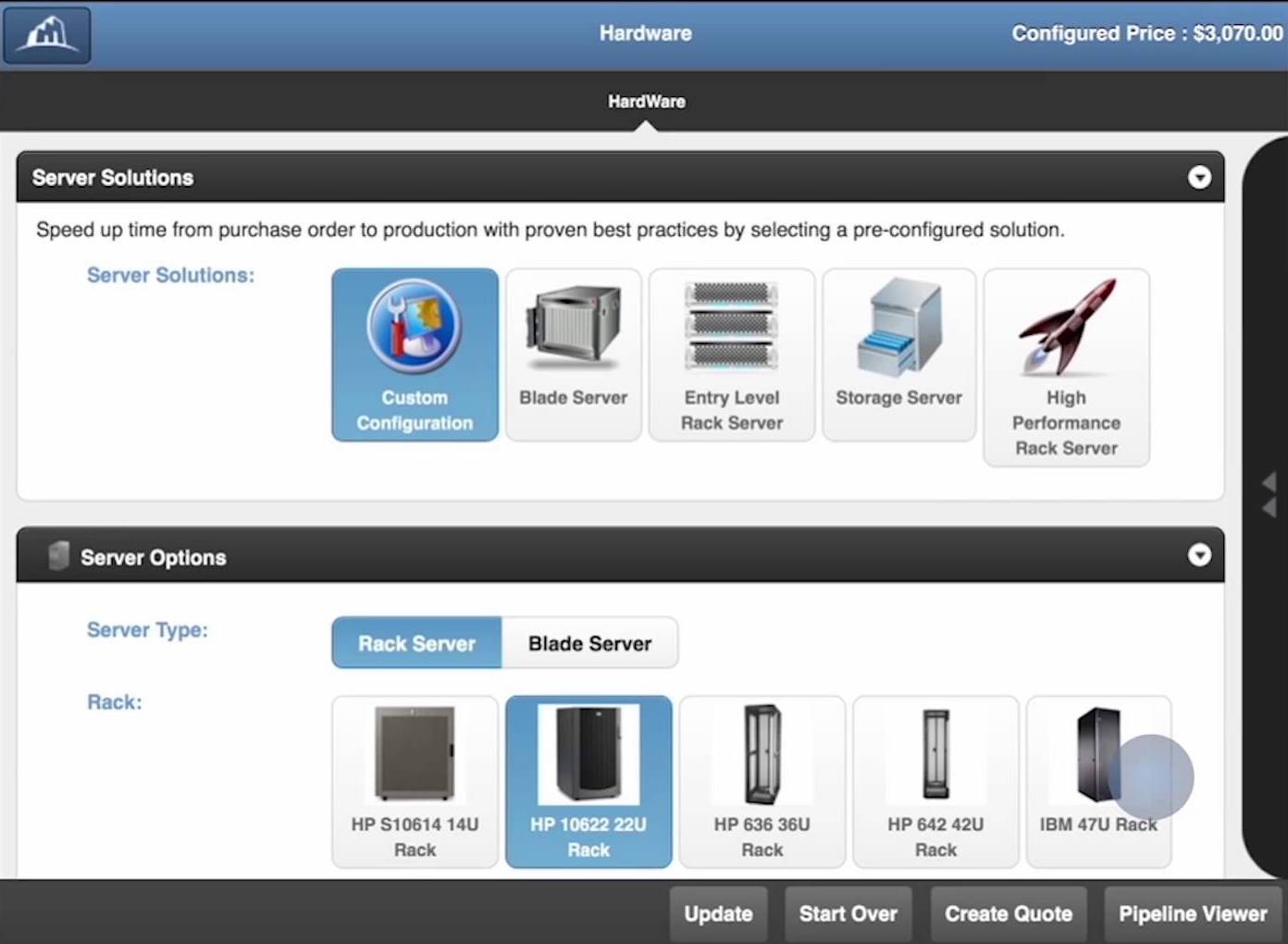

18. Axonom Powertrak CPQ

Axonom’s Powertrak CPQ software solution is a SaaS based tool that is more suited for legacy industries with its target audience being manufacturers and distributors. Axonom’s specialization is in visualization and interactive configuration. Powertrak CPQ is a good fit for companies more interested in rendering visual configurations for their products.

Axonom’s Powertrak CPQ Overview:

- Bottomline: Powerful visualizations with a robust engine.

- Suited CRM: Salesforce, Microsoft Dynamics, Oracle CRM, NetSuite, Exact Macola.

- Pricing: Not disclosed publicly.

- Notable Customers: Boeing, AMD, Intel.

19. Autodesk Configure One CPQ

Autodesk Configure One CPQ is also a tool that is targeted towards manufacturing companies. Like Powertrak CPQ, Configure One also has 3D visualization capabilities and, by its own admission, has a configurator that’s more suited for manufacturing processes. Autodesk provides both on-premise and cloud implementations and has a good set of integrations with major CRM and ERP products.

Autodesk Configure One CPQ Overview:

- Bottomline: Flexible and suited for manufacturing companies of all sizes.

- Suited CRM: Salesforce, Microsoft Dynamics, Oracle CRM.

- Pricing: Not disclosed publicly.

- Notable Customers: Emerson, Mitsubishi, United Technologies.

20. Configit Quote

Configit Quote is a CPQ solution aimed at companies using SAP. Configit Quote uses data available from SAP to build and generate pricing quotes at scale. Configit Quote also provides an intuitive interface for salespersons to quickly adopt and utilize. Salesforce integrations also mean that it can be used as a standalone CPQ software.

Configit Quote Overview:

- Bottomline: Simple to use for managing complex configurations.

- Suited CRM: Salesforce, Microsoft Dynamics.

- Pricing: Not disclosed publicly.

- Notable Customers: ABB, Airedale, GEA Tunchenhagen.

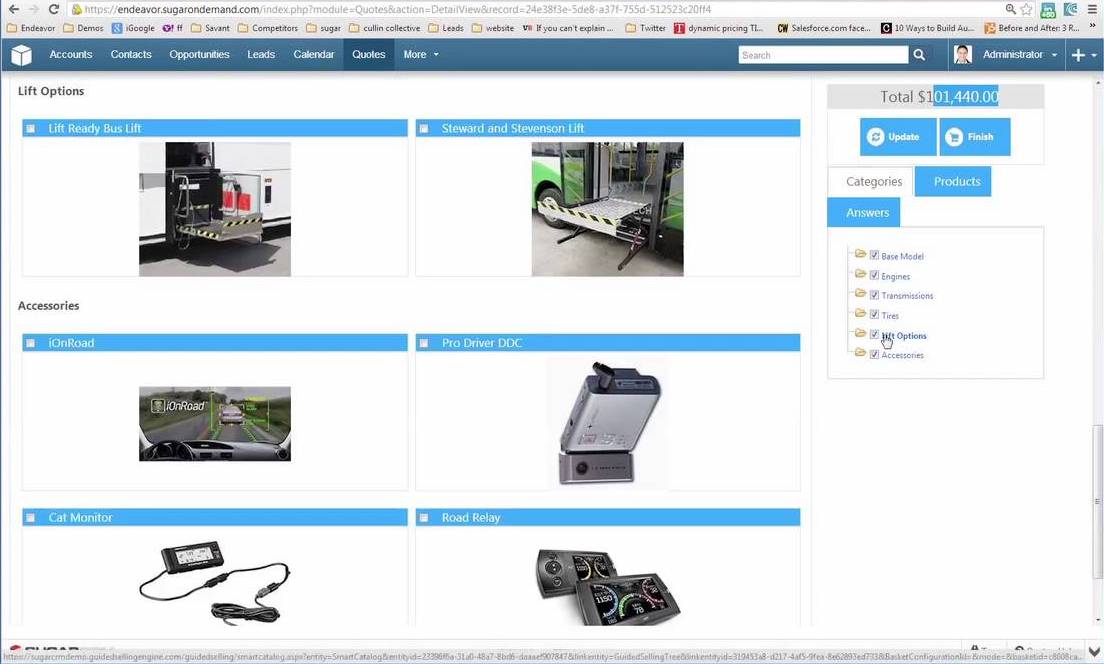

21. EndeavorCPQ

EndeavorCPQ was very recently acquired by Denver based software company Vendavo resulting in complete sales ecosystem. EndeavorCPQ is a well regarded CPQ software with a well-developed pricing engine and an intuitive UI. It also allows for a high level of customizations making it easy for even exceptional situations to be handled. EndeavorCPQ is a very good fit for small and midsized companies with its cloud offering.

EndeavorCPQ Overview:

- Bottomline: Highly customizable and reliable.

- Suited CRM: Salesforce, Microsoft Dynamics, SugarCRM, Infor CRM.

- Pricing: Not disclosed publicly.

- Notable Customers: Nielsen, Okuma, Lutronic.

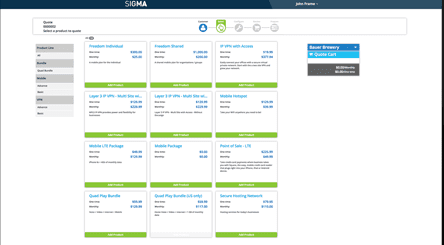

22. Sigma CPQ

Sigma CPQ software is targeted specifically at the communications service provider industry. Sigma CPQ provides for a complex configurator able to work with dynamic pricing structures and can also leverage first and third party data for intelligent recommendations. Sigma also provides a set of other sales applications to integrate with the CPQ software.

Sigma CPQ Overview:

- Bottomline: Targeted industry fit.

- Suited CRM: Salesforce, Microsoft Dynamics.

- Pricing: Not disclosed publicly.

- Notable Customers: Orange Belgium, Windstream Communications, Tiscali.

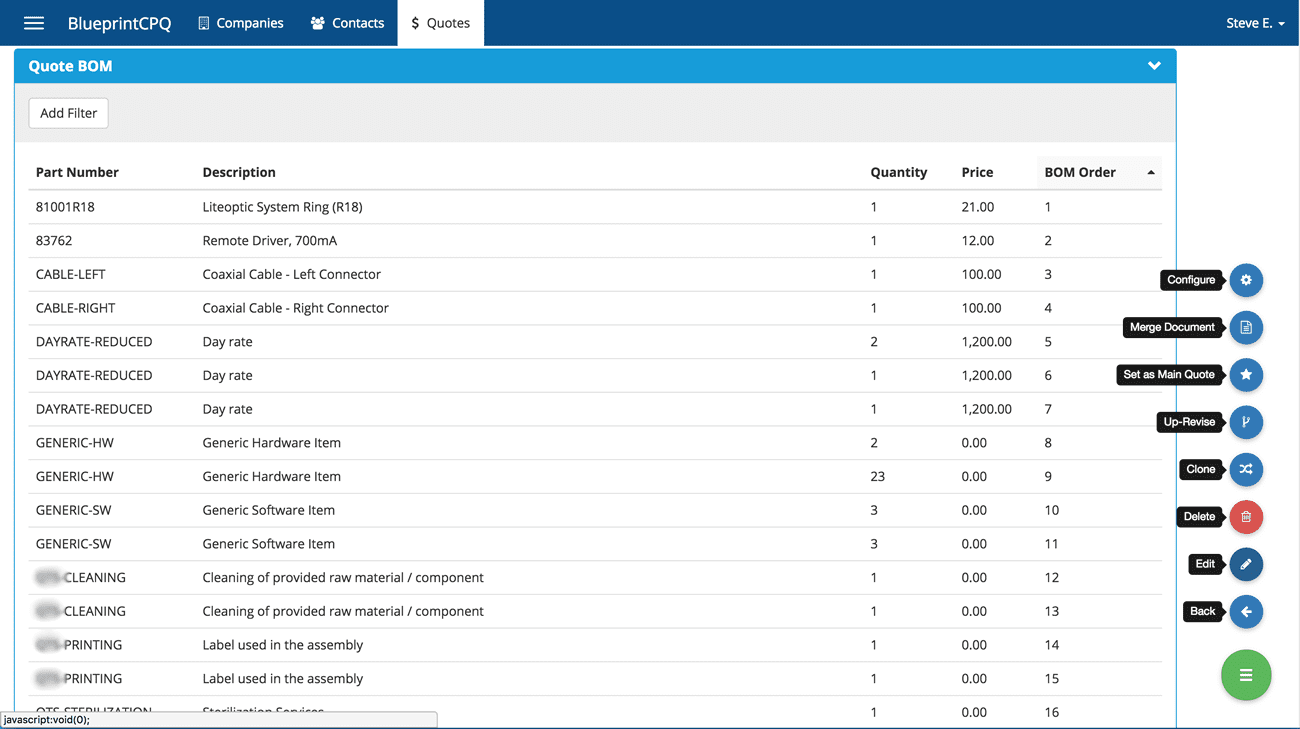

23. BluePrint CPQ

BluePrint’s CPQ tool is highly flexible with niche and custom manufacturing processes making it a versatile solution that can work well in multiple environments. BluePrint is highly scalable while also being able to provide for geography-wise customization of configurators and pricing proposals.

Blueprint CPQ Overview:

- Bottomline: Versatile and Scalable.

- Suited CRM: Salesforce, Microsoft Dynamics.

- Pricing: Not disclosed publicly.

- Notable Customers: English Heritage Buildings, Eurotherm by Schneider, Hagie.

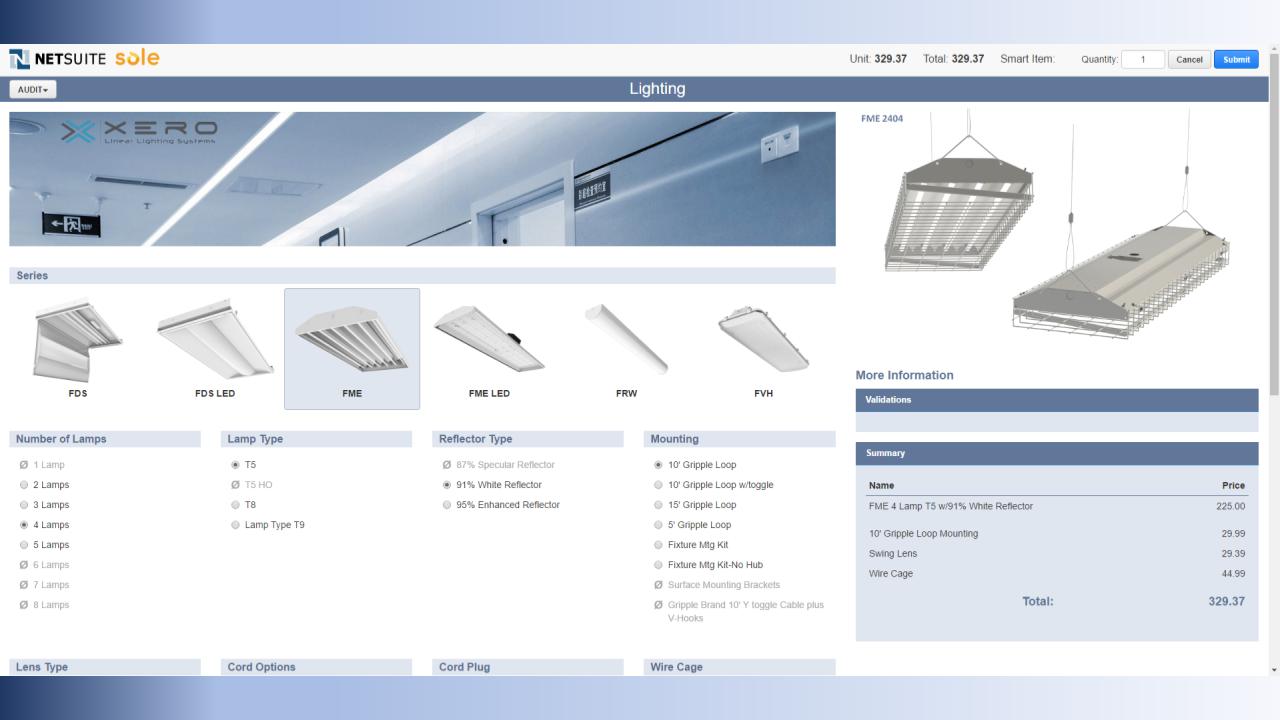

24. Verenia Sole

Verenia Sole is a CPQ application native to NetSuite, in fact, making it the only one. Verenia Sole provides configurator and guided selling modules as part of its CPQ solution. With a good set of core functionalities, Veneria Sole CPQ is good for businesses invested in NetSuite with its Sole variant. But it also has the EOS variant for e-commerce and Aura Quickbooks Online and Zoho CRM.

Verenia Sole CPQ Overview:

- Bottomline: Nativity to NetSuite works to advantage.

- Suited CRM: NetSuite, Zoho

- Pricing: Not disclosed publicly.

- Notable Customers: Freedman Seating Company.

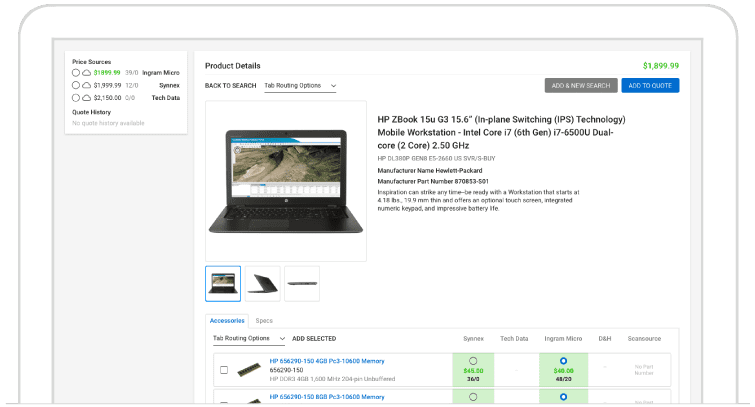

25. ConnectWise CPQ

ConnectWise CPQ is a cloud based solution with a highly intuitive User Interface and some attractive features. It also provides multichannel support for both direct sales and self service customers with multiple integrations.

ConnectWise CPQ Overview:

- Bottomline: Robust and simple to use.

- Suited CRM: Salesforce.

- Pricing: Not disclosed publicly.

- Notable Customers: Not disclosed publicly.

26. QuoteWerks

QuoteWerks provides a turnkey CPQ solution with integrations to multiple CRM and ERP solutions. It is mostly aimed at small and medium businesses providing configuration, guided selling and proposal functionalities.

QuoteWerks CPQ Overview:

- Bottomline: High performance for small businesses.

- Suited CRM: Salesforce, Microsoft Dynamics, SugarCRM.

- Pricing: Standard Edition starting at $199 (One time purchase).

- Notable Customers: Not disclosed publicly.

CPQ software is inherently complicated – just like its CRM counterpart. That means your organization could experience a slow and difficult implementation and adoption process.

Whatfix’s Digital Adoption Platform helps your organization realize the ROI on your CPQ investment with in-app training, personalized onboarding, and self-help support features that integrate directly on top of your CPQ software.

Sign up for a Whatfix demo to improve your team’s CPQ adoption and training now.

Thank you for subscribing!